Zila str 23a, Riga, LV-1007, Latvia. Phone +37167322945. E-mail riga@strek.lv

Technical information

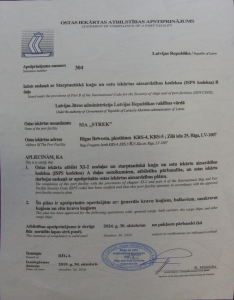

The STREK company was founded on November 14, 1991 and today complies with modern quality standards approved by ISO 9001:2015. Being one of the largest coal transshipment points, after modernization, the terminal is capable of receiving, transshipment and storage of pig iron, coke, timber and other cargoes. The wide cargo areas and complex of powerful equipment are capable of handling 5 million tons per year with a prospective increase to 8 million tons.

WHY IS IT BENEFICIAL?

GENERAL INFORMATION

Thanks to its deep-water berths of 262 and 263 m, STREK serves large-scale cargoes to end consumers in Europe, Latin America, Southeast Asia and Africa, which are transported by Panamax and Baby Cape Size vessels with minimal lead times. Loading speed reaches 40 thousand tons per day. Permissible draft of ships up to 14.5 meters of fresh water above zero level.

INDIVIDUALITY

Sifting-shredding complexes (12 units) ensure production preparation for trade, increasing income for the supplier. The end product is in high demand.

LOYALTY

For many years, stable cooperation has been established with coal mining companies in the Kuzbassa region, metallurgical joint ventures in Russia and many companies in Europe, Asia, China and elsewhere. As a Riga Trade Freeport company, STREK has benefits in the field of tax payment, which it successfully does

After the modernization of berths KRS - 4, KRS - 5 in length of 525 meters, STREK will be able to serve large cargo lots to end users all over the world, serving Panamax, Baby Cape Size, Cape Size ships in the shortest possible time. The permissible draft of ships is 15.15 m at zero fresh water level.

TERMINAL STREK - RIGA

BULK CARGO FOR OCEAN SHIPS

STREK TERMINAL IS AN OPPORTUNITY TO WORK WITH DISTANT MARKETS WITH MAXIMUM EFFICIENCY BY FORMING CARGO BATCHES IN FRONT OF PANAMAX, BABY CAPE SIZE TYPE CARGO VESSELS WITH A CARGO CAPACITY OF UP TO 115 THOUSAND TONNES.

Equipment characteristics

- 11 gantry cranes with lifting capacity from 16 to 63 tons. Bucket capacity from 9 to 18 m3;

- DSC (mobile crushing and screening complexes with magnetic separators) 12 units. The maximum coal processing through DSC can reach 30 thousand tons per day;

- ZP-170 GIPO - 2 units (capacity up to 4500 tons each);

- TITAN-1800 - 7 units (capacity up to 3000 tons each);

- DSB - 3 units (capacity up to 2000 tons each);

WAGON OVERTURNER - CAR TRIPPER

- Unloading performance up to 1000 tons per hour;

- A conveyor line is installed for supplying coal to the ship, which is equipped with magnets for cleaning metallic impurities (SPM). Capacity 2000 tons per hour;

- KRATZER CRANE - performance 1000 tons per hour;

- 2 STUCKERS - performance of each 1000 tons per hour;

Throughput capacity

for the harbor railway station "Krievu sala" 20 million tons. The distance from the station to the terminal is 2.3 kilometers.

Open areas (warehouses) - 35,000 m2

- the norm of simultaneous storage - 220,000 tons.

The norm of loading ships - 20,000 tons per day.

- The maximum possible loading rate is 40,000 tons per day.

One of the most important tasks in the logistics industry is accurate accounting of cargo flow. Implementation of modern control helps with reducing expenses and preventing conflict situations between freight suppliers and receivers, which the STREK company provides with railway wagon and truck scales.

The company STREK received a worthy estimation on the international arena for its high achievements in the field of commercial activity.

In 2008 in Madrid, STREK company was awarded with the new Millenium Award "INTERNATIONAL TRANSPORT AWARD" for its achievements in business and trade.

In 2010 in Geneva, STREK company received THE INTERNATIONAL PLATINUM TECHNOLOGY AWARD FOR QUALITY AND BEST TRADE NAME from President of Association otherways management & consulting Paris-France.

In 2005 and 2010 STREK company received awards from Riga Freeport as the best stevedoring company of Riga Freeport.

STREK has also received ISO 9001 certification, confirming the quality of its process management.

Magnetic cleaning

In 2017, STREK invested in a magnetic cleaning system. As a result, these actions have led to the fact that the terminal can now provide 100% magnetic cargo cleaning and provide the best quality products to the end customer. Three-stage cleaning of cargo from foreign bodies proved its worth. Modern and specialized magnets installed on the terminal guarantee product quality.